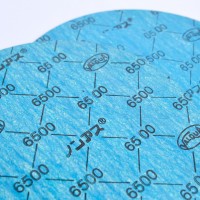

Gasket is a packing designed for inclusion between rigid mating parts in essentially stationary relationship to prevent leakage. They are found in flange joints, machine and process plant assemblies. Gaskets are produced in various shapes, sizes, ratings and designs out of different materials for the medium to be contained.

Gaskets are categorized as Metallic, Semi-Metallic and Non-Metallic (Soft) gaskets and each serves a different and specialized purposes. Our gaskets are made according to ASME, DIN, JPI, JIS, BS and API standards.

Certificates

- Gasket test

- Fire Test

- Fugitive Emissions

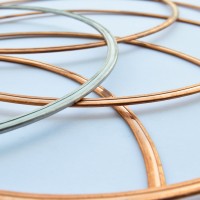

Spiral Wound with inner and outer ring

Spiral Wound with inner and outer ring Spiral Wound with outer ring

Spiral Wound with outer ring Spiral Wound with inner ring

Spiral Wound with inner ring Spiral Wound only

Spiral Wound only